Latest News

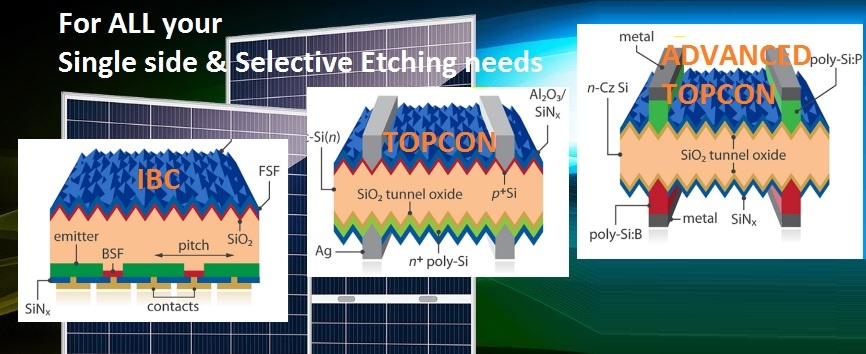

22/08/23 Selective etching for Advanced TOPCON & IBC

The ADE process meets the selective etching requirements of upcoming "Advanced TOPCON" solar cell architectures and IBC.

14/11/22 ADE for TOPCON cells - EUPVSEC 2022

In Milan's conference, Fraunhofer ISE presented its latest TOPCON cell developments, featuring ADE poly etching.

28/03/22 SiliconPV conference 2022

NINES PV will attend the 12th International conference on Crystalline Silicon Photovoltaics in Konstanz, Germany.

> EUROPEAN INNOVATION FOR GLOBAL SOLAR CELL MANUFACTURING

ADE can scale to multi-GW levels, resulting in very low cost of ownership. It is currently the only scalable industrial dry etching process available for the photovoltaic market. Our SINGLE SIDE ETCHING process enables advanced cell architectures (TOPCON, TOPCON2 (Advanced TOPCON), IBC, PERL, PEROVSKYTE...), through for exemple the removing of poly-silicon wrap around, the selective etching and patterning or edge isolation of solar cells. Our advanced SINGLE SIDE Nano-TEXTURING process is now being developped specifically for high efficiency monocrystalline cells, enabling a path toward lower front surface reflectance, leaner process flow and lower ligth angle dependance for higher product yield and efficiency. It's nano features have the potential to facilitate the deposition of PEROVSKYTE layers, for tandem solar cell architectures.

"Innovation is essential to meet the challenges of scaling photovoltaic manufacturing and solar renewable energy"

>>>FIND OUT MORE ABOUT OUR  OFFERINGS & APPLICATIONS <<<

OFFERINGS & APPLICATIONS <<<

ADE allows to switch to any type of silicon wafer and provide a range of advanced processes including a very selective single side etching and edge isolation. Compatible with thin wafers, as low as 100um, and roll to roll process; fluorination of films is also possible.

A novel silicon wafer etching technology designed for your advanced industrial manufacturing requirements.

Dry Etching tools engineered to meet the needs of the Terra Watt age - enabling high volume & low cost production.

Check out our latest TOPCON application for poly-Si removal.

Nines PV is an equipment manufacturer for the solar industry. The company is headquartered in Dublin, Ireland.